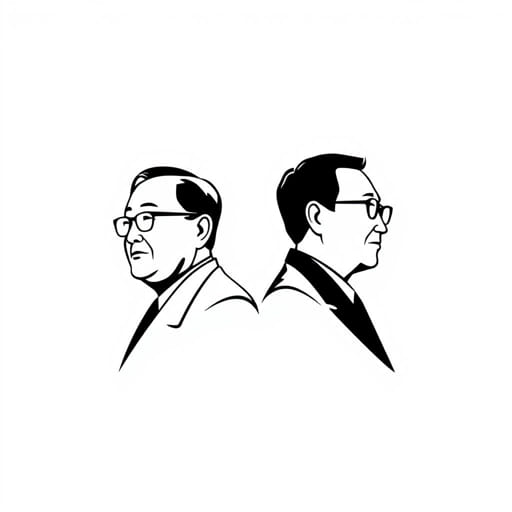

During Japan’s post-war economic recovery, two visionaries Eiji Toyoda and Taiichi Ohno emerged as key figures who revolutionized the global manufacturing industry. Their work at Toyota Motor Corporation not only transformed the company into a worldwide leader in automobile production but also introduced principles that would influence business practices across industries. Their collaboration gave birth to the Toyota Production System (TPS), a groundbreaking approach to efficiency, quality, and continuous improvement. By understanding the contributions of Eiji Toyoda and Taiichi Ohno, one can appreciate the roots of lean manufacturing and how innovation can arise from necessity.

Eiji Toyoda: The Strategic Leader

Background and Early Life

Eiji Toyoda was born in 1913 into the Toyoda family, which founded what would become Toyota Motor Corporation. After graduating from Tokyo Imperial University, he joined the family business and soon took an interest in the automobile sector. At a time when Japan was struggling to catch up with Western industrial capabilities, Eiji believed that innovation and efficiency were the keys to competing on a global scale.

Visit to Ford and Lessons Learned

In 1950, Eiji Toyoda made a pivotal visit to the Ford Motor Company’s manufacturing plant in the United States. There, he observed the mass production techniques that had made Ford a dominant force in the automotive world. Although he admired the speed and scale of Ford’s operations, he also noticed significant inefficiencies such as overproduction, waste, and lack of flexibility.

These observations had a profound effect on Toyoda. He envisioned a system that would maintain high efficiency but eliminate the waste he had witnessed. Upon returning to Japan, he collaborated with Taiichi Ohno to begin developing what would become the Toyota Production System a unique model tailored to Japan’s economic conditions and cultural strengths.

Guiding Toyota’s Global Expansion

As managing director and later president of Toyota, Eiji Toyoda provided the leadership and vision to implement TPS across the company. Under his guidance, Toyota focused on quality control, customer satisfaction, and long-term planning. His strategic thinking helped turn Toyota from a domestic manufacturer into a global powerhouse. Eiji Toyoda’s legacy lies not just in his title, but in his lasting influence on how businesses can achieve world-class productivity.

Taiichi Ohno: The Architect of Efficiency

Innovative Thinking on the Factory Floor

Taiichi Ohno joined Toyota in 1932 as a shop-floor engineer. With a background in mechanical engineering, he had a deep understanding of manufacturing processes. Ohno was particularly focused on reducing waste and improving workflow. While Toyoda provided the vision, Ohno was the practical mind who turned ideas into reality through experimentation and refinement.

The Creation of the Toyota Production System

Ohno’s biggest contribution was the formalization of the Toyota Production System. He introduced key concepts that redefined how manufacturing should operate. These included:

- Just-In-Time (JIT): Producing only what is needed, when it is needed, and in the amount needed.

- Jidoka (Autonomation): Equipping machines and workers with the ability to detect problems and stop production to prevent defects.

- Kaizen: The philosophy of continuous improvement involving every employee, from executives to line workers.

- Elimination of Muda: Identifying and removing all forms of waste (inventory, motion, waiting, overproduction, etc.).

These principles empowered Toyota’s workforce and created a flexible, efficient, and responsive production system. Unlike traditional mass production, TPS emphasized flow, quality, and adaptability, which gave Toyota a competitive edge.

Training and Cultural Change

Ohno understood that a production system is only as good as the people who operate it. He dedicated significant time to training workers, fostering a culture of accountability, and encouraging problem-solving at all levels. He would often challenge workers with difficult tasks and guide them to discover solutions on their own. This approach cultivated a workforce that was engaged, informed, and capable of making decisions on the factory floor.

The Partnership Between Toyoda and Ohno

What made the collaboration between Eiji Toyoda and Taiichi Ohno so powerful was their complementary strengths. Toyoda provided the strategic vision and corporate backing needed to implement sweeping changes across the organization. Ohno, on the other hand, developed the operational tools and processes that made the vision a reality.

Together, they created a dynamic model that balanced innovation with practicality. Their work was not an overnight success but rather the result of years of experimentation, feedback, and iteration. The effectiveness of their partnership continues to be studied in business schools and manufacturing industries worldwide.

Global Influence of Their Ideas

Lean Manufacturing and Beyond

The success of the Toyota Production System eventually caught the attention of global competitors. Western manufacturers, especially in the United States and Europe, began studying Toyota’s methods in an effort to regain competitiveness. This led to the development of lean manufacturing, a term coined to describe the principles behind TPS.

Lean manufacturing has since been adopted across various sectors, from healthcare and software development to logistics and construction. The concepts of waste elimination, continuous improvement, and employee empowerment have reshaped how organizations think about productivity and quality.

Legacy in Modern Business Practices

Even decades later, the contributions of Toyoda and Ohno remain highly relevant. Their insistence on innovation, quality, and respect for people has become a blueprint for sustainable business success. Concepts like Just-In-Time inventory systems, Six Sigma, and Agile development all draw inspiration from the work done at Toyota.

Their influence is evident in the widespread use of tools such as:

- Kanban boards for workflow visualization

- 5 Whys root cause analysis

- Standardized work procedures

- Value stream mapping

These tools, rooted in the original ideas of TPS, continue to drive efficiency and innovation in businesses across the globe.

Eiji Toyoda and Taiichi Ohno were more than just industrialists they were visionaries who challenged conventional thinking and reshaped the future of manufacturing. Their combined efforts led to the development of a revolutionary production system that prioritized efficiency, quality, and human potential. By turning constraints into opportunities, they laid the foundation for Toyota’s global success and inspired a movement that transformed industries worldwide.

Their legacy serves as a powerful reminder that innovation does not always require massive resources it often begins with asking the right questions, observing deeply, and empowering people at every level of an organization. Eiji Toyoda and Taiichi Ohno showed the world what is possible when leadership and ingenuity come together with purpose.